Products | Support Services | Field Support Team

Welcome to the premier destination for the lithium extraction industry, where you'll discover how Swagelok can revolutionize your operations. As a global leader in fluid system technologies, Swagelok brings unparalleled expertise and cutting-edge solutions to this rapidly expanding field. With our extensive range of products and services tailored specifically for the lithium extraction industry, we empower companies to optimize their processes, enhance reliability, and drive success. Explore the benefits of partnering with Swagelok:

- Unrivaled Reliability: Swagelok products are engineered to deliver exceptional performance, even in the harshest operating conditions. Our fittings, valves, tubing, and instrumentation offer secure connections, corrosion resistance, and leak-tight performance, ensuring the reliability and integrity of your fluid systems. Trust Swagelok to keep your operations running smoothly and efficiently.

- Design and Assembly Services: We understand that each lithium extraction operation is unique. That's why Swagelok provides tailored solutions that address your specific challenges and requirements. Our team of experts collaborates closely with you, offering personalized support in fluid system design, installation, and maintenance. Benefit from Swagelok's unmatched industry knowledge and experience to optimize your processes and achieve operational excellence.

- Enhanced Safety: Safety is paramount in the lithium extraction industry, and Swagelok is committed to providing products and services that prioritize the well-being of your workforce and equipment. Our high-quality components and systems help create a safe working environment, while our safety-focused services, including training and education, equip your personnel with the necessary skills and knowledge to operate Swagelok products safely and effectively.

Lithium Extraction Applications

Swagelok products and services find valuable applications in the lithium extraction process. Here is a list of areas where Swagelok products and services are commonly utilized in lithium extraction:

Lithium Brine Processing: Swagelok products, including fittings, valves, and tubing, are used in the processing and handling of lithium-rich brine solutions. They provide secure connections, corrosion resistance, and leak-tight performance, ensuring the integrity and efficiency of brine processing systems.

Lithium Carbonate Production: Swagelok products and services play a role in the production of lithium carbonate, a key compound used in lithium-ion batteries. They provide reliable connections, precise flow control, and corrosion resistance, ensuring the safety and efficiency of the production process.

Lithium Pilot Plants: Swagelok products and services are utilized in pilot plants for lithium extraction and processing. They provide reliable and precise fluid handling components, instrumentation, and system design expertise, enabling the development and optimization of extraction techniques on a smaller scale.

Lithium Research and Development: Swagelok products support research institutions and laboratories in their lithium-related studies. Whether it's fittings, valves, tubing, or instrumentation, Swagelok products provide reliable and customizable solutions for fluid handling, enabling precise control and accurate measurements in lithium research and development projects.

Products for Lithium Extraction

Swagelok offers a range of products that can be utilized in the lithium extraction process. Some of the key types of Swagelok products applicable to this process include:

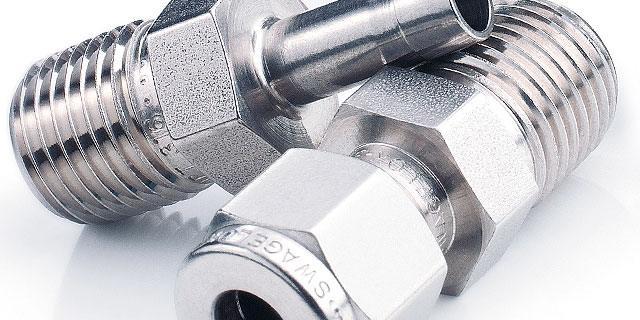

Fittings

Swagelok offers a range of fittings specifically designed for the unique demands of the lithium extraction market. These fittings, such as compression fittings and tube adapters, ensure secure and leak-tight connections in fluid handling systems. They are engineered to withstand the corrosive nature of lithium fluids, providing reliable performance and minimizing the risk of leaks or system failures.

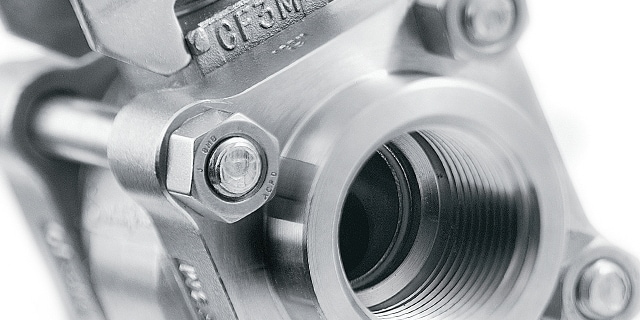

Valves

Swagelok valves are well-suited for the lithium extraction process, where precise flow control and system isolation are crucial. Ball valves, needle valves, and check valves from Swagelok are constructed with materials that offer excellent resistance to lithium corrosion, ensuring reliable operation and preventing contamination of the extracted lithium.

Tubing and Accessories

Swagelok's tubing solutions for the lithium extraction market are designed to transport lithium fluids efficiently while maintaining system integrity. Seamless stainless steel tubing and welded tubing options are available, both of which offer excellent corrosion resistance and durability, ensuring safe and reliable fluid transport throughout the extraction process.

Hoses and Flexible Tubing

Swagelok's hoses and flexible tubing solutions provide versatile and reliable connections in the lithium extraction industry. These products are designed to handle the corrosive nature of lithium fluids, offering flexibility and mobility where required. Swagelok hoses and flexible tubing enable efficient fluid transfer while minimizing the risk of leaks or system failures.

Regulators

Swagelok regulators play a vital role in maintaining consistent pressure levels during lithium extraction. These regulators are designed to handle the specific pressure requirements of the process, allowing for precise control and optimal performance. They ensure that the pressure is maintained within the desired range, facilitating efficient and safe extraction operations.

Filters

Swagelok filters are essential for maintaining the purity and quality of the extracted lithium. These filters effectively remove contaminants, particulates, and impurities from the fluid stream, ensuring that the lithium remains clean and uncontaminated throughout the extraction process. Swagelok offers a range of filters with various filtration ratings to meet the specific needs of the lithium extraction market.

Pressure Measurement

Swagelok pressure gauges are high-quality and reliable instruments used for measuring pressure in various industrial applications. Designed and manufactured by Swagelok, a renowned provider of fluid system solutions, these gauges offer precise and accurate pressure readings, ensuring safe and efficient operation of systems.

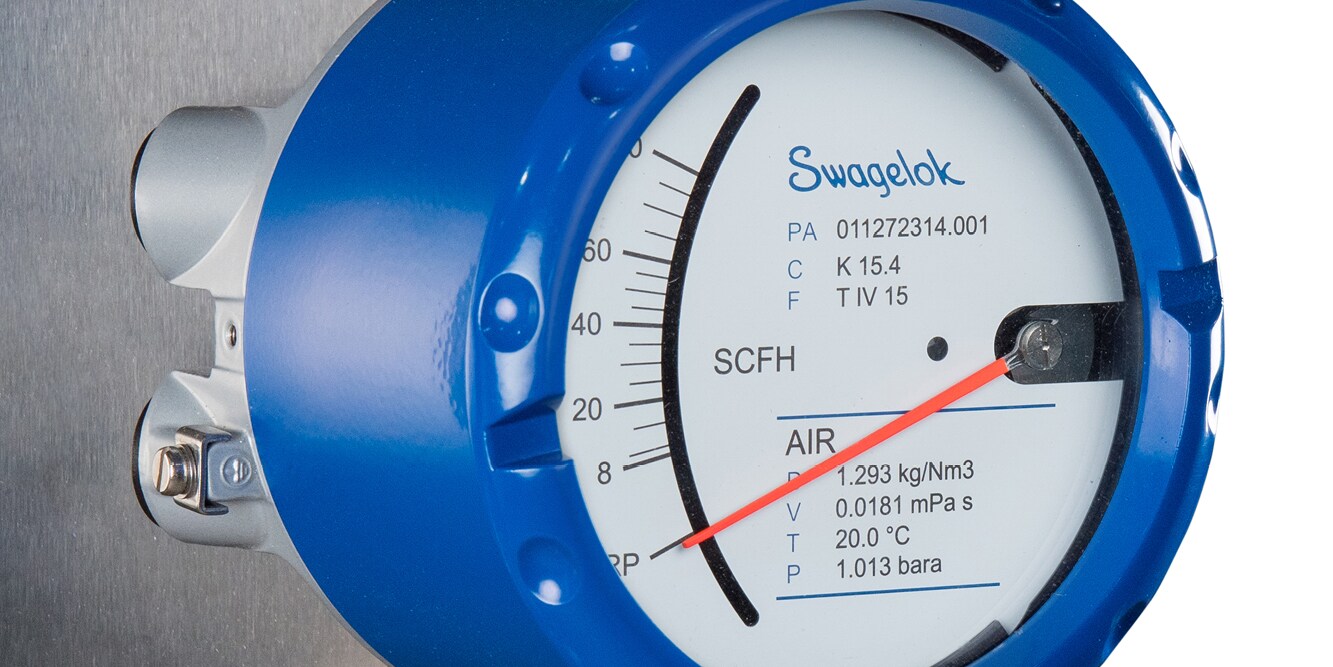

Flow Measurement

Swagelok flow meters are precision instruments designed to accurately measure the flow rate of fluids and gases in various industrial applications. These flow meters are manufactured by Swagelok, a reputable provider of fluid system solutions. Swagelok flow meters utilize advanced technology and high-quality materials to ensure reliable and repeatable measurements.

Support Services for Lithium Extraction

Swagelok's support services are designed to provide comprehensive support and expertise to the semiconductor industry. With their deep understanding of fluid system technologies and industry-specific challenges, Swagelok's support services team of collaborates closely with lithium manufacturers to optimize operations and ensure peak performance. Here are three key support services offered by Swagelok that benefit the lithium extraction:

Field Engineering

Swagelok has field engineers positioned around the globe who can visit your facility promptly, collaborate with your team, and then assess and evaluate all known (and unknown) issues

Onsite Services

Boost system safety, performance, and efficiency with prioritized, actionable recommendations from Swagelok experts based on fluid and sampling system site surveys, hose advisors' observations, or steam system audits.

Vendor Managed Inventory

Swagelok's Vendor Managed Inventory (VMI) services provide a streamlined and efficient solution for businesses looking to optimize their supply chain management. With Swagelok's VMI services, businesses can rely on a collaborative partnership with Swagelok as their trusted vendor, ensuring a consistent and reliable supply of Swagelok products.

Design and Assembly Services

Receive design consultation and professional assembly of high-quality standard and configurable fluid subsystems constructed and tested according to best practices.

Training

Swagelok Training offers comprehensive programs designed to enhance your knowledge and skills in fluid system technology. Learn the fundamentals of fluid system components, installation, maintenance, and troubleshooting. Gain hands-on experience with Swagelok products, applications, and best practices, equipping you with the expertise to optimize fluid system performance and reliability. Accelerate your proficiency and confidence in fluid systems with Swagelok Training.

Our Field Support and Sales Team

Our field engineers and sales representatives work together to provide comprehensive solutions to your fluid system-related challenges. They are located locally. Our team can assist you in the following areas:

- Regulatory Compliance: Our experts help you continuously meet the increasingly stringent safety and emissions regulations through effective leak detection and risk mitigation strategies.

- Sales Support: Our sales representatives collaborate closely with our field support team. They provide assistance in understanding your unique needs and requirements, ensuring that the solutions we offer align with your goals. Our sales team is dedicated to delivering exceptional customer service and helping you make informed decisions.

- Productivity Enhancement: We assist in maximizing productivity and yields from your fluid systems by offering design enhancements and troubleshooting services. Our team identifies areas for improvement and implements solutions to optimize your operations.

- Cost Reduction: By minimizing maintenance requirements and improving system performance, we help you reduce operating costs throughout your facilities. Our experts analyze your systems to identify opportunities for efficiency gains and cost savings.

- Knowledge Transfer: In cases where valuable business knowledge has been lost due to employee turnover, we provide consultation and training services to replace that knowledge. Our team works with you to understand your specific requirements and develops tailored training programs to bridge the knowledge gap.