![]()

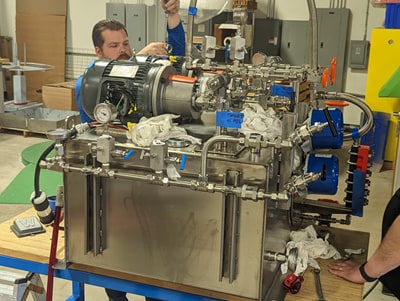

Recent Project: Sample Conditioning Panel for Steam Condensate Sampling Incorporating a Heat Exchanger, Flow Transmitter, and pH Probe

Request Additional Information

![]()

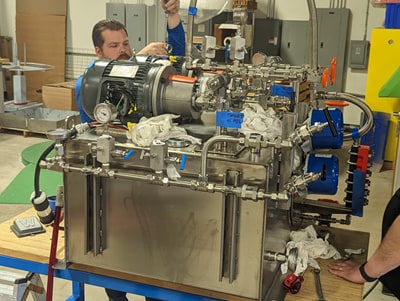

Recent Project: Two-Phase Sampler for a Hydrotreater Unit. This Panel Allows for Sampling Either a Liquid Sampler or the Resulting Vapor Off-Gas

Request Additional Information

![]()

Recent Project: Seal Support Panel for a Local Refinery: This is an API 72/76 Design with Monel Components for Use in an Alky Unit

Request Additional Information

System Design and Fabrication | Assembly Services | Tubing Services | Electrical System Services | Testing Services | Additional Services

Custom Design and Assembly Services

Welcome to Swagelok Design and Assembly Services, where precision meets efficiency. With decades of expertise and a commitment to excellence, we offer a comprehensive range of solutions to meet your fluid system needs. From tubing services to automated system design and fabrication, including Front End Engineering Design (FEED) support and estimate services for skid-based systems and large-scale projects, we provide tailored solutions that adhere to the highest standards of quality and safety. Explore our capabilities and discover how Swagelok can elevate your systems to new heights of performance and reliability.

System Design and Fabrication

- Front End Engineering Design (FEED) Support / Estimate Services for skid based systems or larger project opportunities

- Sampling and sample conditioning system design and fabrication

- Sample cylinder design and assembly

- Seal support system design and fabrication

- Gas distribution system design and fabrication

- Regulator system design and fabrication

- Custom sampling probe design and

fabrication

- Test equipment

|

|

|

Assembly Services

- Assembly of medium and high-pressure fittings/tubing (from 1/4” to 9/16” diameters)

- Customizable hose assembly and testing for aerospace, food and beverage, life sciences, and more

- GTAW orbital welding per Boiler and

- Pressure Vessel code ASME Section IX (from 1/8” to 4” diameters)

- VCO/VCR fitting installation for welded systems

- Setting of Swagelok adjustable check and relief valves

- Assembly of actuators, switches, beacons, and solenoids on Swagelok valves

|

Tubing Services

- Stock tubing sizes consultation

- Tube cuts (1/16” thru 4” diameters, lengths up to 20’)

- Tube bending (1/8” thru 2” diameters)

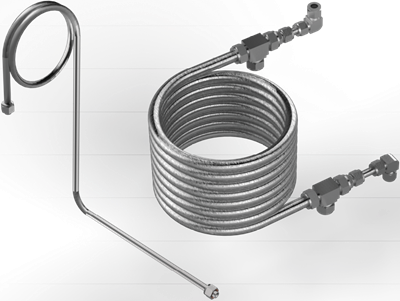

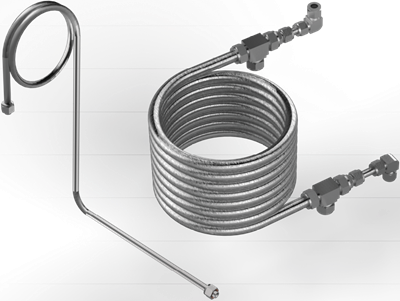

- Tube coiling (1/4” thru 1/2” diameters, coil diameters from 4 1/4” to 52”)

- Tube-in-tube coiling (1/4” thru 1/2” diameters, coil diameters from 4 1/4” to 52”)

- Tube fitting swage (from 1/16” to 2” diameters)

- Pipe fitting installation (from 1/8” to 2” diameters)

- PFA tube flaring (from 1/4” to 1” diameters)

|

|

|

Electrical System Services

- Basic electrical system design and installation (up to 240 VAC / 60 VDC, max current draw of 20 A)

- Wiring of components such as solenoids, valves, sensors, switches, etc.

- Functional testing of electrical components within a larger fluid system (up to 240 VAC / 60 VDC, max current draw of 20 A)

|

Testing Services

- Leak testing with filtered Nitrogen (N2) (up to 1,000 psig)

- Hydrostatic leak testing with water (H2O) (up to 20,000 psig)

- Inboard to 9.86 x 10^-13 std cc/sec leak rate

- Outboard to 9.86 x 10^-8 std cc/sec leak rate

|

|

|

Additional Services

- Laser etching and annealing of various materials (stainless steel, aluminum, wood, leather, engineered plastics) up to 24”x36”x10”

- Laser cutting of engineered plastics up to 24” x 36” x 1/4” thick

|

Ready to optimize your fluid system with Swagelok’s expertise? Contact our team today to discuss your specific requirements and learn how we can tailor our services to meet your needs. Whether you need precision tubing, reliable assembly, or innovative system design, our team is here to support you every step of the way. Reach out now to start your journey towards enhanced performance and efficiency.