A Caution on Intermixing Twin Ferrule Tube Fittings

Intermixing Twin Ferrule Tube Fittings – Is it Safe?

Whether you choose Swagelok, or any other tube fitting manufacturer to work alongside your team, we want what is best for your organization, your bottom line, and your safety. Depending upon who you talk to, you may hear different perspectives about the safety and reliability of intermixing and interchanging components (bodies, nuts, and ferrules) of different tube fitting manufacturers.

We stand behind the idea that the intermix / interchange is not a best practice, can be risky, may lead to costly leakage, and can result in safety issues. Regardless of your position on the matter; our goal is to help you make an informed decision when choosing the right tube fitting for your fluid system applications.

Below you will find an independent third party review regarding the intermixing and interchanging components from Swagelok tube fittings as well as three other industry leaders.

What's Inside the Independent Study?

- Journal of Engineering Design, Vol.10, No.4 - citing seven industry publications

- 26 pages including peer review, scientific testing, and Finite Element Analysis

- Six data point conclusion validating the belief that intermix/interchange can lead to system issues, leakage, and safety concerns

Summary

"This paper presents the findings of an independent study carried out to examine the effects of intermixing the component parts of twin ferrule tube fittings manufactured by four different companies. Experimental tests and finite element analysis has shown that the swaging and sealing mechanisms of fittings are different despite seeing geometric similarities. It was evident that no two companies produced components to the same dimensional or metallurgical specification and that pressure testing alone should not be used as the only means of validation.

The ERA plots of intermixed fittings show that a form of sealing occurred in some combinations which could lead to acceptance. However, it was not until further engineering assessment was made could it be seen that the sealing methods were not as originally designed and therefore a high-risk factor must be applied. In addition to the design safety factors being compromised any intended sealing mechanism either became superfluous or over-stressed. Other components were stressed to levels in some unintended way and often were found to impede the movement of other parts and acting as a conduit or fatigue failure."

Conclusion

- Divergent range of sealing surfaces are created due to design, construction, and torque value differences

- Different sealing surface incompatibilities exist due to geometry, tolerances, and metallurgic properties

- Intermixing components as described in this study could lead to compromised function

- Undesirable stress concentration can be caused by intermixing leading to fatigue failure

- Series of movement measurements provide strong evidence that intermixing components can create ineffective sealing surfaces resulting from different swaging mechanisms, material hardness, and tolerance variations

- Pressure testing should not be used as the only means for compatibility verification. FEA plots of intermixed fittings demonstrate that a “form of sealing” occurs, however, a “high risk factor must be applied to such combinations.”

Regardless of your choice to use Swagelok, another tube fitting manufacturer, or some combination thereof - we hope that this information will be useful in making the decision that is right for your business, your people, and the specific applications you encounter on a daily basis.

How we can help

Knowledgeable Associates

We invite you to take a peek behind the scenes at our incredible associates who keep our company -- and yours -- running!

Locally Stocked Products

Come see us at one of our three authorized Swagelok sales and service centers in Kansas City, Little Rock, and Omaha – to take advantage of each location's stocked warehouse, will call counter, and customer service representatives ready and willing to assist you.

Certified Training

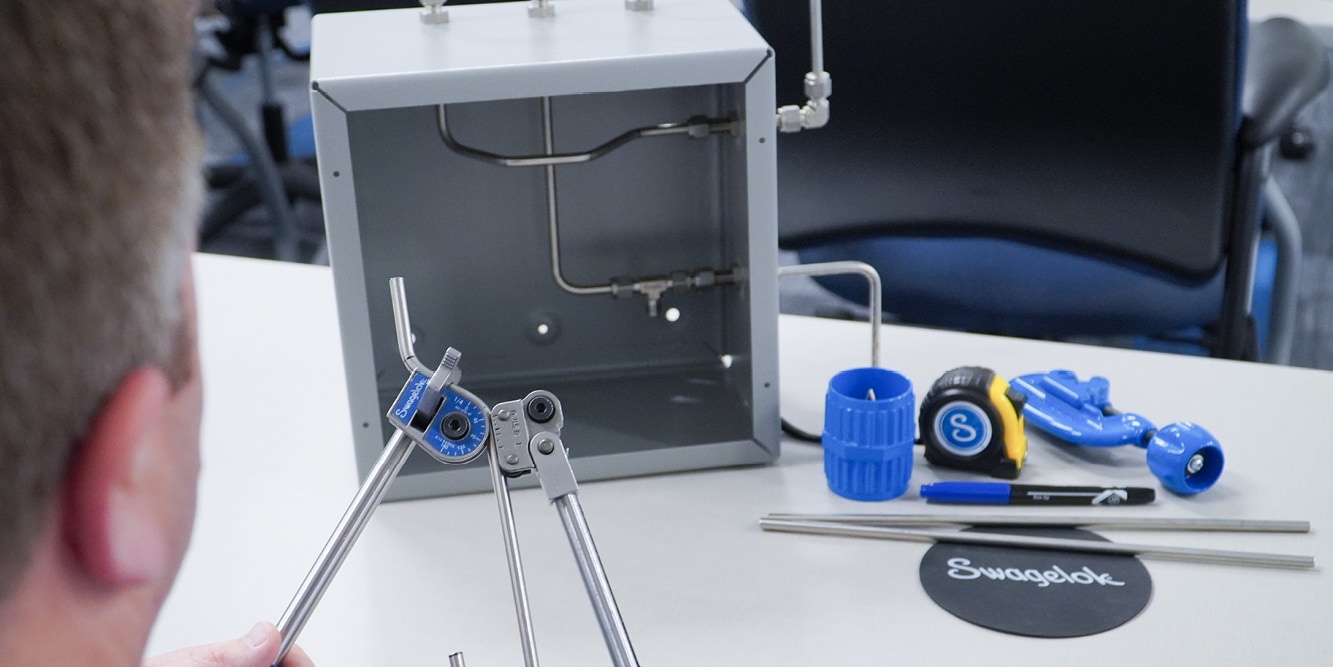

Swagelok Essentials training course provides critical skills for developing, building, and maintaining dependable fluid systems.