Products | Engineering Services | Field Engineers

Swagelok delivers significant benefits to the cannabis industry, specifically in essential oil extraction, through its unwavering reliability, top-notch quality, and deep expertise.

- Reliability: Swagelok products ensure consistent performance and minimal downtime, guaranteeing a dependable essential oil extraction process.

- Quality: With precision and craftsmanship, Swagelok components meet rigorous industry standards, helping cannabis businesses produce premium extracts while ensuring compliance with regulations.

- Expertise: Swagelok's experienced team offers tailored solutions, optimizing efficiency and safety in extraction processes, and driving innovation and growth in the cannabis sector.

Cannabis Applications

Swagelok's versatile products find essential applications in the cannabis industry, from precise extraction processes to analytical instrumentation and gas delivery systems, ensuring quality control and efficiency throughout the production cycle.

Cannabis Extraction: Swagelok products are essential in cannabis extraction processes, providing reliable fittings and valves for precision control of critical fluids.

Analytical Instrumentation: Swagelok components are widely used in analytical instruments, ensuring precise fluid handling and measurement accuracy in cannabis testing laboratories.

Gas Delivery Systems: Swagelok's expertise in gas delivery systems is invaluable for maintaining purity and consistency in the production of specialty gases used in cannabis processing.

Products for the Cannabis Extraction

Swagelok's high-quality products are instrumental in enhancing the cannabis extraction process. Our reliable fittings, valves, and tubing components ensure a seamless and efficient operation, minimizing downtime and maximizing productivity. By maintaining stringent quality standards, Swagelok supports cannabis businesses in producing top-tier extracts that meet regulatory requirements. With our expertise and tailored solutions, we empower the cannabis industry to achieve consistent and safe extraction processes, ultimately contributing to the production of premium-quality cannabis products.

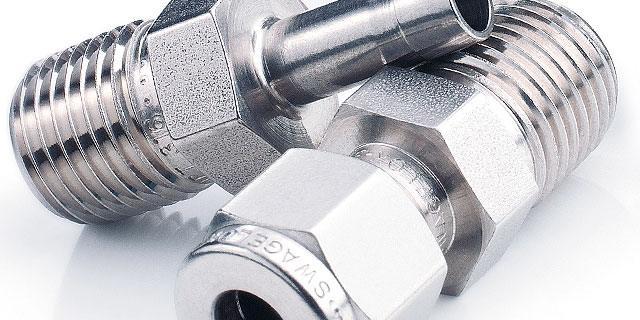

Fittings

Swagelok fittings play a pivotal role in cannabis extraction equipment, ensuring precise and leak-tight connections for solvents, gases, and extracts, contributing to safety and process efficiency.

Valves

Swagelok valves provide accurate control over fluid and gas flow rates, optimizing cannabis extraction parameters and maintaining product quality.

Hoses

Swagelok hoses are crucial for managing fluid flow and maintaining pressure, ensuring reliability and consistency throughout the extraction process.

Regulators

Swagelok regulators precisely control gas pressure, essential for maintaining optimal extraction conditions and product quality.

Measurement Devices

Swagelok's measurement devices monitor critical parameters such as pressure and temperature, facilitating the maintenance of optimal extraction conditions and product consistency.

Tubing and Accessories

Swagelok's high-quality tubing and accessories are essential components in cannabis extraction equipment, ensuring precise fluid handling and maintaining the integrity of the process. These components contribute to reliable and efficient extraction operations while meeting industry standards for quality and safety.

Engineering Services for the Cannabis Industry

Swagelok's engineering services offer tailored solutions that can greatly benefit the cannabis extraction industry. With deep expertise in fluid system design and optimization, Swagelok engineers can collaborate with cannabis businesses to create efficient and safe extraction processes. Whether it's designing custom fluid handling systems, ensuring regulatory compliance, or troubleshooting existing systems, Swagelok's engineering services empower cannabis extraction operations to maximize productivity, maintain product quality, and adapt to evolving industry requirements, ultimately contributing to their long-term success and competitiveness.

Onsite Services

Boost system safety, performance, and efficiency with prioritized, actionable recommendations from Swagelok experts based on fluid and sampling system site surveys, hose advisors' observations, or steam system audits.

Design and Assembly Services

Receive design consultation and professional assembly of high-quality standard and configurable fluid subsystems constructed and tested according to best practices.

Field Engineering

Swagelok has field engineers positioned around the globe who can visit your facility promptly, collaborate with your team, and then assess and evaluate all known (and unknown) issues

Our Field Engineers

Our field engineers can help you develop effective responses to your most pressing fluid system-related challenges. They are located locally and across the globe and regularly collaborate with one another to find the best solution to customer challenges. They can help you determine how to:

- Continuously meet tougher regulatory demands related to safety and emissions through leak detection and risk mitigation

- Increase productivity and yields from your fluid systems through design enhancements and troubleshooting

- Reduce operating costs throughout your facilities by minimizing maintenance requirements and improving system performance

- Maintain or increase overall profitability by making uptime and process improvements

- Replace business knowledge that has “walked out the door” with former employees through consultation and training

Meet Our Local Field Engineers

Sam Polise

Director of Engineering Services

Jonathan Smith

Field Engineer

Ryan Oatman

Field Engineer