Customizable, Locally Crafted, and Dependable Grab Sampling Solutions for Gas and Liquid Applications

Discover our fully customizable, locally manufactured, and dependable grab sampling assemblies tailored to meet your specific requirements. With advanced features designed for the secure capture of liquid or gas samples from your process lines, our offerings cater to diverse configurations. Whether you prefer closed-loop sampling into pressure-rated sample cylinders or opt for collecting process fluid into cost-effective glass laboratory bottles for analysis, our selection of sampling panels ensures safety, user-friendliness, and easy maintenance, available for ordering with a single part number.

Swagelok Grab Sampling Panels

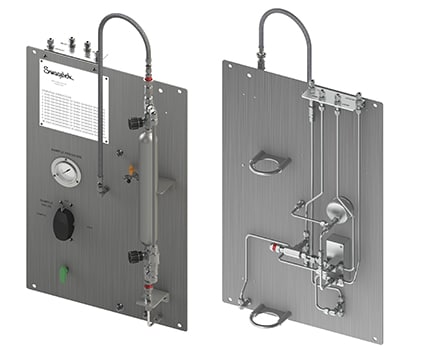

Swagelok Grab Sample Module (GSM)

Enhance your sampling capabilities with the Swagelok® Grab Sample Module (GSM), a closed-loop sampling system drawing from a positive-pressure process. Our GSM, utilizing differential pressure, efficiently returns the sample to the process at a lower pressure point. The robust, pressure-rated metal grab sampling cylinders (GSC) secure samples, offering foolproof protection for operators.

Key Features of the GSM

- Switching valve configuration for seamless fluid routing control

- Two or three Swagelok® 40G series ball valves for enhanced operational clarity

- Continuous circulation within the GSC to maintain optimal process conditions

- Optional rupture disc and relief valve for added safety measures

- Swagelok® tube fittings for minimal leak potential

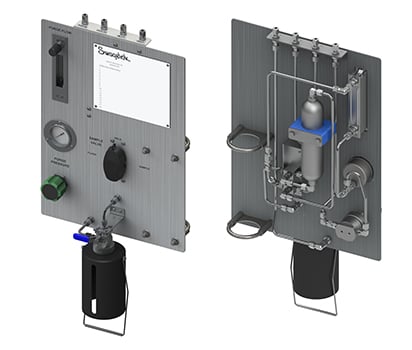

Swagelok Grab Sample Liquid (GSL) Systems

Elevate your liquid sampling experience with the Swagelok® Grab Sample Liquid (GSL) system. Tailored for drawing fluid into non-pressure-containing bottles with self-sealing septum caps, the GSL excels in applications where process fluid stability at atmospheric pressure is crucial.

Key Features of the GSL

- Fixed-volume systems with a switching valve for simplified operation

- Swagelok tube fittings for leak-free performance

- Compatibility with glass or polyethylene laboratory bottles

- Immediate visual feedback on sample stream quality

- Secure sample drawing mechanism with spring-return handle

Swagelok Grab Sampling Valve

Address safety, maintenance, and quality challenges by incorporating the Swagelok® Grab Sampling Valve into your fluid system. Our leak-free design, replacing rubber O-rings with Swagelok® tube fittings, ensures reliable performance.

Key Features of the Grab Sampling Valve

- Easy needle replacement with all-metal seals

- Improved needle design to minimize coring and clogging

- Interchangeable shroud options for various sample bottles

- Elastomer-free design to minimize potential leaks

- Spring-return handle for precise sample collection

Designed by Swagelok Engineers. Optimized for You.

Trust in Swagelok's commitment to safety, ease of use, and reliable results. Our grab sampling systems are meticulously designed to protect personnel and enhance profitability. Configured locally by fluid system specialists, each system is tailored to your specifications and comes with the Swagelok Limited Lifetime Warranty.

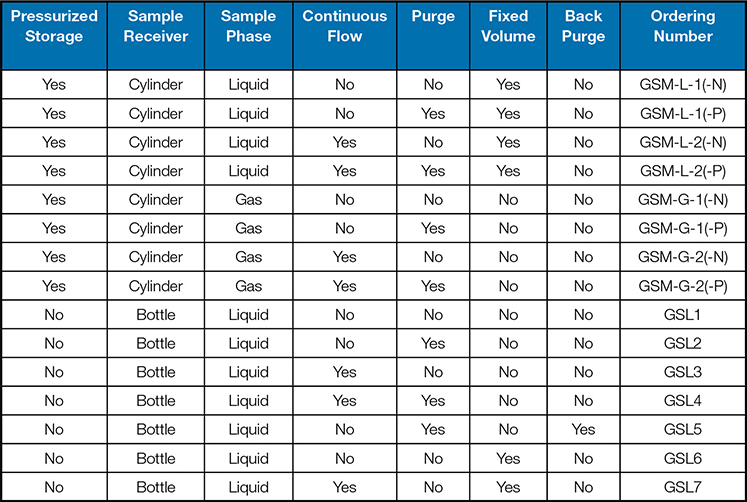

Convenient Standard Assemblies Tailored to Your Needs

Both GSM and GSL sampling system panels are available in fixed-volume versions to prevent overfilling and overpressure. Customize your system with additional instrumentation, sample coolers, automation, exotic alloys, mounting options, and more.

What to Expect When Ordering Swagelok Grab Sampling Systems

Ensure a seamless process when acquiring Swagelok grab sampling systems:

- Assess: Evaluate your current sampling system with assistance from our sampling specialists for improved operational performance and safety.

- Recommend: Based on your parameters, a certified Swagelok engineer recommends the ideal panel, considering temperature, pressure, phase, container type, materials, and installation location.

- Configure: Customize your solution using our standard designs, substituting products, adding valves, and making layout changes.

- Assemble: We handle the assembly, testing, and certification, ensuring your panel meets strict guidelines and specifications.

- Train: Receive hands-on training for system use and maintenance, empowering your technicians to prevent and address issues.

Trust an Industry Leader in Sampling. Trust Your Results. Discover the benefits of Swagelok grab sampling solutions and leverage local support from sampling system specialists for added value to your organization.