Variable Area Flowmeters: A Simple, Reliable, and Cost-Effective Way to Measure Fluid Flow

A Simple, Reliable, and Cost-Effective Way to Measure Fluid Flow

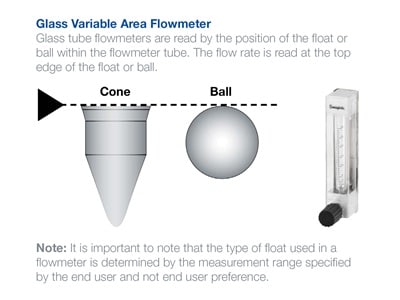

A variable area flowmeter (VAF) is a flow measurement device that operates on the principle of allowing fluid flow to pass around a float housed in a tapered tube. As flow force increases (normally from higher flow rates), the float moves up the tapered tube to allow for more flow area around the float. The measured flow rate then corresponds to the location of the float within the tube.

The components within a variable area flowmeter are minimal, which makes it a simple and reliable method to measure flow.

As with most measurement components, there is a scale that measures flow from either the top of the ball or a needle indicator.

The ratio of the maximum reading to the minimum reading is referred to as the turndown ratio and is commonly a 10:1 ratio for most variable area flowmeters. In other words, flowmeters cannot read down to zero flow, and this turndown ratio correlates to the complete range of flow values that a single flowmeter can accurately measure.

Standard Swagelok® variable area flowmeters are factory calibrated to their media, flow range, and accuracy class using clean, dry air for air-flow range models, and water for water-flow range models. Standard units of measure marked on the scale are calibrated to:

- 17.4 psia (1.2 bar) and 68°F (20°C) for G1, G2, G3, GM, and GP models.

- 14.7 psia (1.013 bar) and 68°F (20°C) for G4, M1, M2, M4, and M4H models.

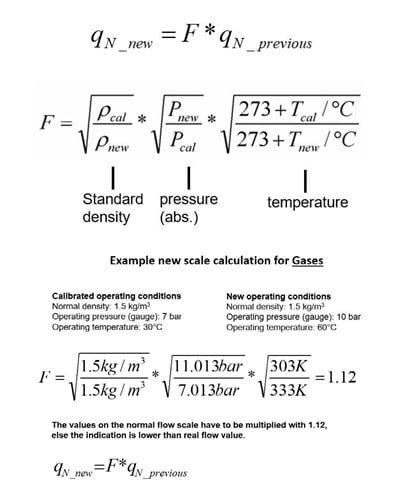

Custom-calibrated flowmeters are available for fluids with properties substantially different from those of air or water, as well as systems operating at higher pressures or temperatures. In liquids, higher temperature can reduce viscosity and density, resulting in lower readings. In gases, higher fluid temperature can increase volume and result in higher readings. Increased pressure can compress gases and lead to lower meter readings. Knowing the specific application fluid properties will enable a custom calibration to provide more accurate and direct readings of the fluid flow. These include the following:

- Fluid to be measured.

- Fluid dynamic viscosity, typically in cP or mPa-s, or kinetic viscosity, typically in cSt or m2/s, at operating pressure and temperature.

- Fluid density in lb/ft3 or kg/ m3 at operating pressure and temperature.

- Fluid temperature at operating conditions, with unit of measure.

- Fluid pressure at operating conditions, with unit of measure.

- Flow measurement range and unit of measure.

Alternatively, in the case of periodic equipment calibration; it may be necessary to validate the flow readings from a master flowmeter to a calibration unit. In this case, it may be necessary to correct the readings of both devices to ensure the readings are accurate.

Variable area flowmeters are simple, reliable devices used to measure fluid flow. The device operates by allowing fluid to pass around a float in a tapered tube. These devices are most accurate when the float is calibrated for a specific fluid, density, pressure and temperature and are a great addition for a fluid system requiring flow control and measurement.