Reducing Fugitive Emissions: A Closer Look at Method 21

A Closer Look at Method 21

Valve leak rates are normally expressed as gas flow rates (usually standard cubic centimeters per second.) In Title III regulations, however, leaks are defined in terms of gas concentration in the atmosphere near the potential leak point, usually in parts per million (ppm) as measured by a portable gas analyzer, instead of the more familiar gas flow rate. There is no direct conversion between gas flow rate through a leak and the gas concentration near a potential leak point. The EPA established Method 21, which details the leak detection and measurement methods which must be used to determine VOC (Volatile Organic Compounds) leaks from process equipment. The primary method utilizes a portable instrument to locate and detect VOC leaks from process, but is not used to quantify the leakage rate. A second, alternative screening procedure is also detailed. This method utilizes a soap solution or other liquid leak detector such as Snoop to detect the presence of leaks. This method may be used under the following conditions:

- Does not have continuously

moving parts - Do not have surface

temperatures greater than

boiling point or less than the

freezing point of the soap

solution - Do not have open areas to

the atmosphere that the soap

solution cannot bridge - Do not exhibit evidence of liquid

leakage

If the above conditions are met, you may spray a soap solution over all potential leak sources. If no bubbles are observed, the source is presumed to have no detectable emissions and may be considered passing requirements.

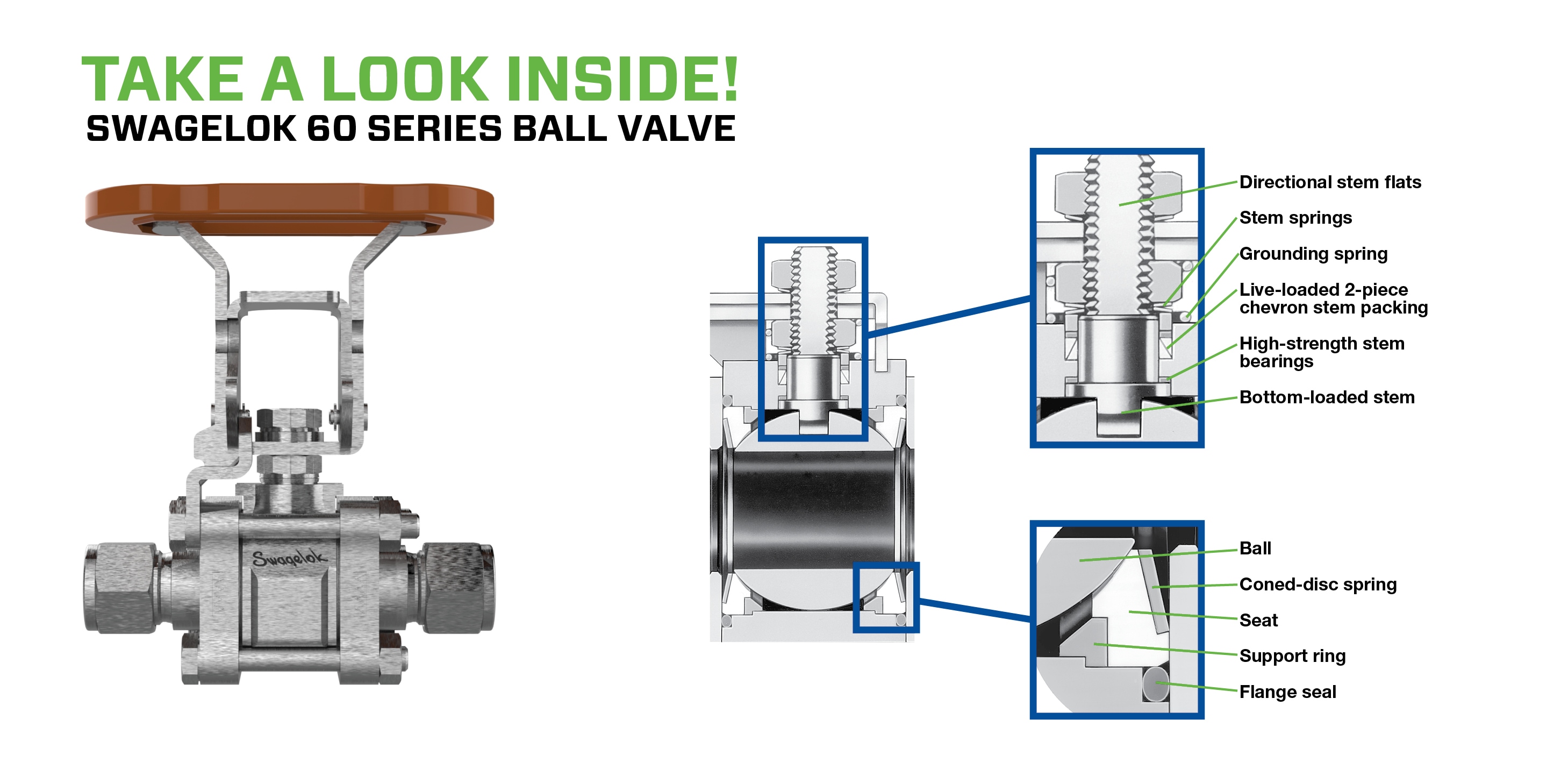

Swagelok shell tests most of its valves with liquid leak detector as normal practice, with no detectable leakage as the pass/fail criteria. This includes most all needle valves, manifolds, check valves and metering valves. Swagelok offers a Low-E-100 certificate for its 60 Series Ball Valve indicating compliance. Swagelok bellow sealed valves and diaphragm valves are tested to even more stringent standards.

When you specify Swagelok valves on a project, you know that each valve is factory tested to exacting standards and will generally meet or exceed the requirements of EPA Method 21 when new (out of the box). Once the valves have been in service, packing adjustments may need to be made periodically to the valve to bring the valve back into compliance. If compliance with EPA Method 21 is essential to your project, specifying Swagelok valves removes a variable. Please contact your Swagelok salesperson if you have any questions.