Making the Switch: Save Both Time and Money Going From Pipe to Tube

Save Both Time and Money Going From Pipe to Tube

There is usually more than one way to do anything, and that includes moving fluid from Point A to Point B. Piping will do it, but so will tubing – and tubing is often lighter, simpler to use and eliminates costly, problematic leak points. Process systems, steam systems and hydraulic systems ¾” and up have traditionally been installed using screwed, flanged or socket welded pipe, because, “That’s the way we’ve always done it." Yet the same logic taken from your instrumentation applications can be directly applied to changing your small-bore piping systems to tubing with the same benefits while realizing a significant decrease in installation time, easier maintenance and with a higher degree of safety and reliability.

There is usually more than one way to do anything, and that includes moving fluid from Point A to Point B. Piping will do it, but so will tubing – and tubing is often lighter, simpler to use and eliminates costly, problematic leak points. Process systems, steam systems and hydraulic systems ¾” and up have traditionally been installed using screwed, flanged or socket welded pipe, because, “That’s the way we’ve always done it." Yet the same logic taken from your instrumentation applications can be directly applied to changing your small-bore piping systems to tubing with the same benefits while realizing a significant decrease in installation time, easier maintenance and with a higher degree of safety and reliability.Strength in Tubing

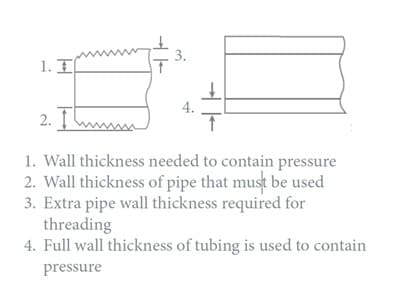

You might wonder how strong tubing is compared with pipe of the same internal size. The pipe is heavier and has a thicker wall, but the thick wall is not needed to contain system pressure. That extra material is there so that it can be cut away to create the threads. If you build this system out of pipe, it will be much heavier, requiring more pipe hangers versus using less expensive tubing clamps. A heavier system also puts greater strain on the supports. Tubing, on the other hand, is sealed on its outside diameter and the wall thickness is used primarily for safe pressure containment, providing an improved strength-to-weight ratio.

Cost Savings Benefits

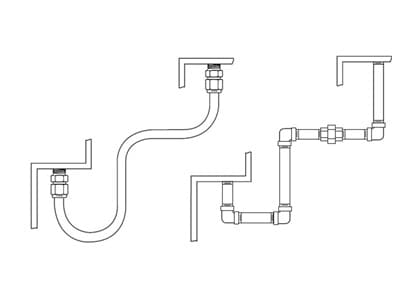

While you have the same issue of supporting the pipe in welded systems, you have the additional concerns of permitting, fire watch, welder skill set, helper costs and all the potential associated post weld requirements: dye penetration, radiography, weld coupons, etc. All these extra costs are eliminated when you employ larger diameter fittings, valves and tubing. The biggest cost savings involves the ability to bend the tubing. In any pipe system a change of direction is accomplished using a fitting, adding additional potential leak points and labor time, creating turbulence and increasing your pressure drop. Being able to bend the tubing reduces the number of fittings required, thereby minimizing pressure drop and conserving energy. Using stainless steel tubing and fittings also provides a cleaner system than pipe: less scale, particulate generation, filler material and a significant reduction in threaded connections.

Meeting Your Specs

Meeting Your Specs

One of the biggest misconceptions is, “I can’t use it because my system pressure and temperature won’t allow it.” Over the years, the quality of tubing due to requirements of ASTM specifications has improved, allowing for higher pressures and temperatures. In fact, 1” OD tubing by 0.095” wall is rated to 3600 psi. ASTM-specified tubing also carries a maximum temperature rating of 1000°F. Larger diameter fittings and tubing CAN meet your most rigorous system conditions and be installed faster, cheaper and perform leak-tight!

Small Bore in Action

Recently, a client needed help with their compressed gas system throughout the entirety of their plant. The system ran at 3500 psi at ambient temperature

and they used 1” OD X 0.095” wall stainless steel tubing. The client purchased seventy-six 1” OD union elbows for tight changes of direction in their system, but were able to avoid purchasing nearly 450 additional elbows by being able to bend the tubing and use offsets. Utilizing tubing instead of a pipe system saved not only time, but also saved money and potential lost time while promoting a higher degree of safety for their plant and associates.

Don’t be fooled by the thin profile; for many applications, tubing is simply better.