From Tap to Transmitter

Enclosure Recommendations for Three Instruments

This could be achieved without a heated enclosure, but the spec calls for enclosures in lieu of insulation. Why? Because the end user wants access to the transmitter, to the manifold and the blowdown valves without having to temporarily un-wrap a cluster of field insulation to isolate and service highly important instrumentation.

The often-unforeseen consequence is that by trying to cram three differential pressure (DP) transmitters, manifolds, impulse lines and especially double blowdown valves into a single triple enclosure, you have potentially created a sizable headache for whoever will be integrating the instrument enclosures and for whoever will ultimately have to operate it. The problem is that the “off-the-shelf" triple enclosure dimensions from most (if not all) enclosure manufacturers are simply too small to effectively house this equipment.

The often-unforeseen consequence is that by trying to cram three differential pressure (DP) transmitters, manifolds, impulse lines and especially double blowdown valves into a single triple enclosure, you have potentially created a sizable headache for whoever will be integrating the instrument enclosures and for whoever will ultimately have to operate it. The problem is that the “off-the-shelf" triple enclosure dimensions from most (if not all) enclosure manufacturers are simply too small to effectively house this equipment.

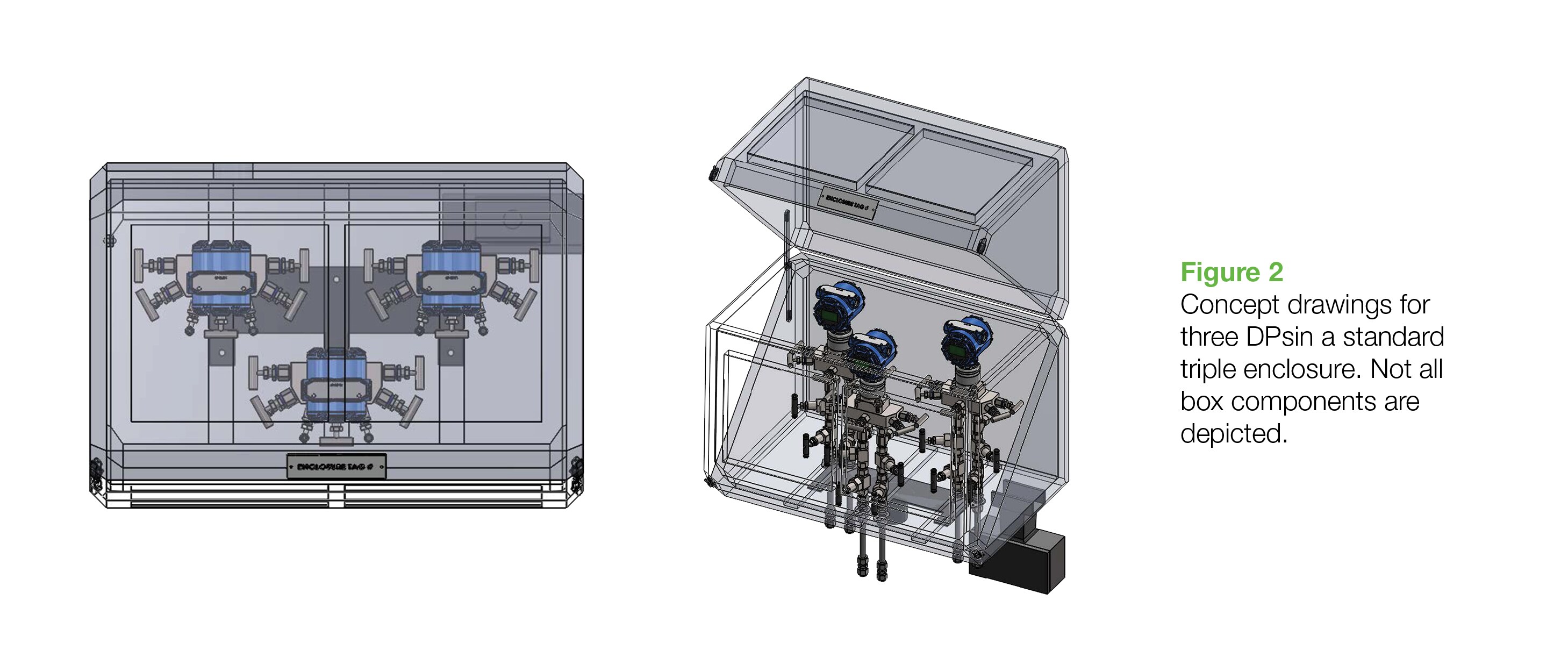

Properly designed ahead of time, these configurations can be achieved, albeit with drawbacks to the end user. Take the Figure 1 example. In order to fit inside of a “triple” enclosure, these transmitters had to be turned upside down. While, in practice, this may improve the function of the transmitter by helping vent the impulse lines, this is an unusual configuration and plant personnel like what they are used to. Moreover, there is compromised access to the blowdown valves, with pinch points and spatial issues that make valve actuation a major challenge.

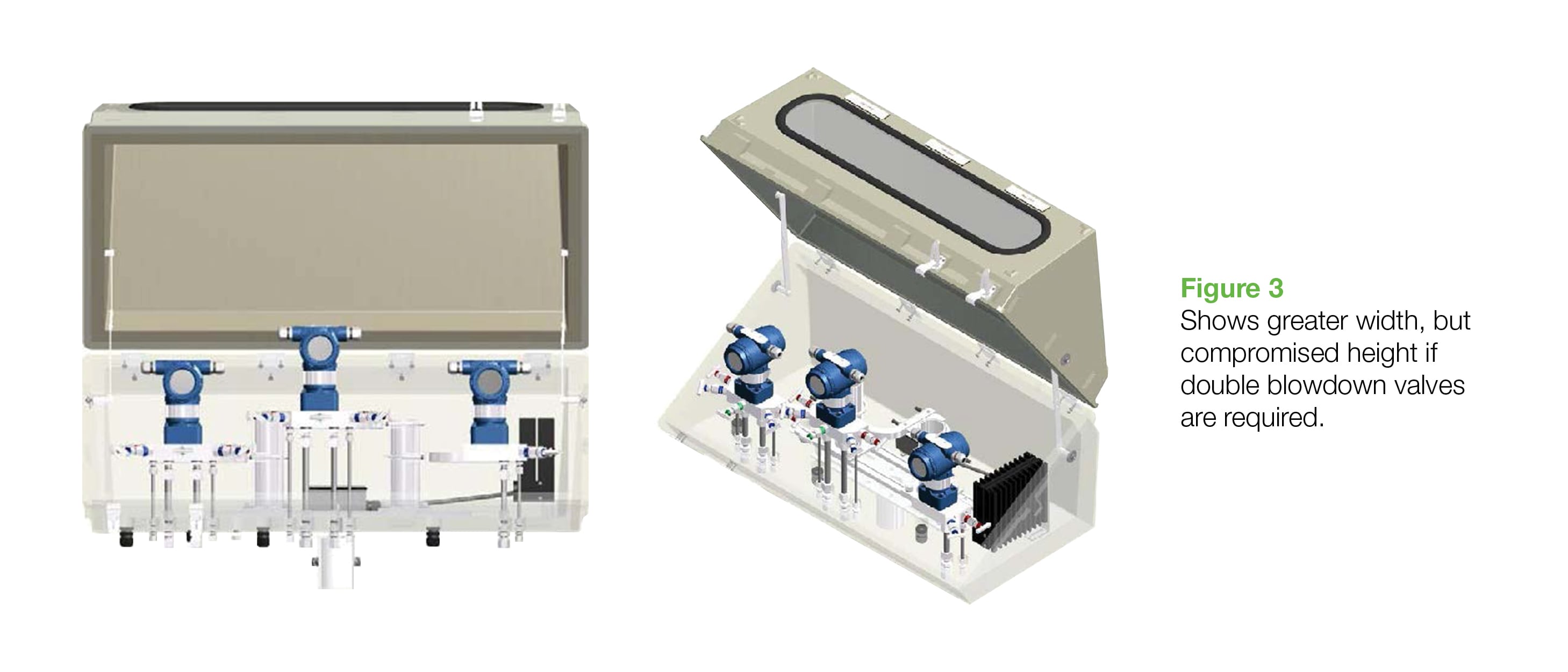

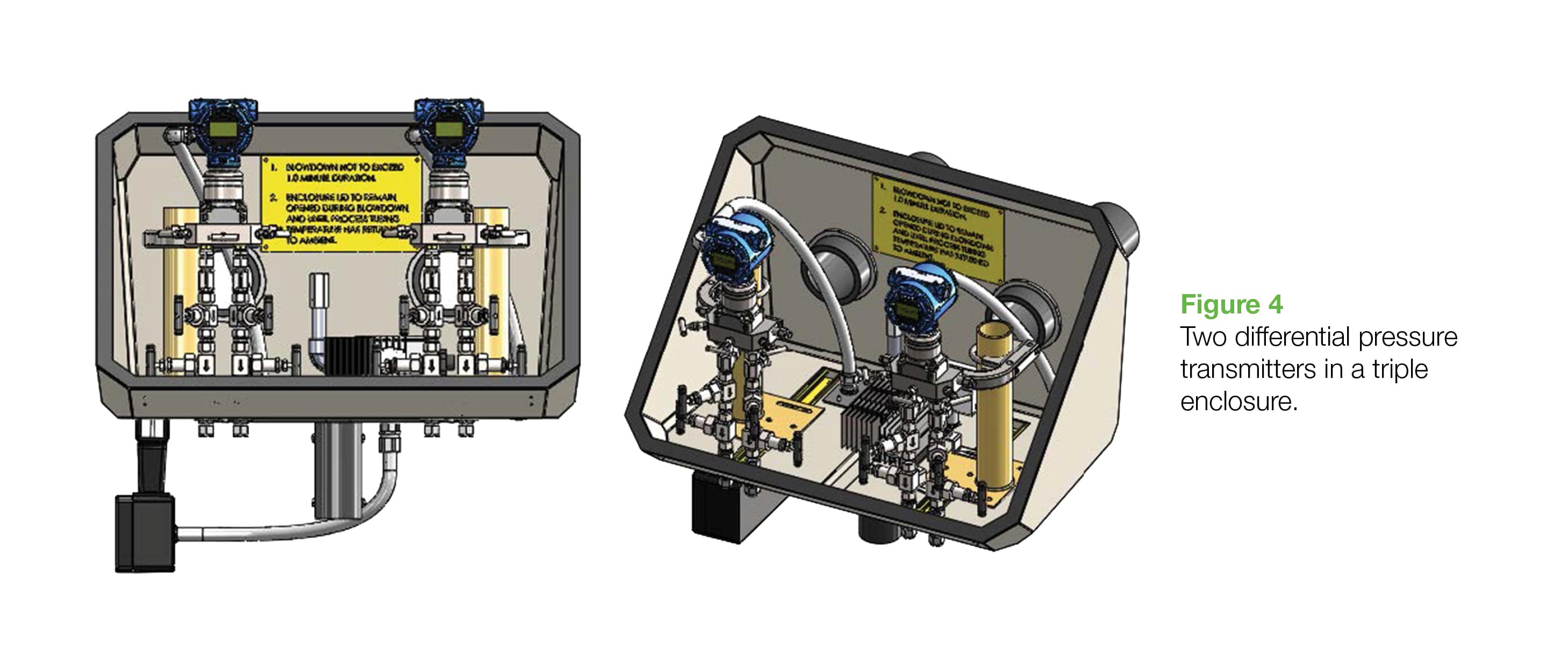

Other configurations just may flat out not work. Different transmitter manufacturers have different dimensions and use different manifolds, so the space to work with is variable. Moreover, the number of impulse line penetrations and heat shrink entry seal boots can create issues with rear entry into the enclosure. For three DP level transmitters, it is possible to have six independently routed impulse lines, and six separate entry seal boots. See the concept drawing in Figure 2. The graphic does not depict the internal mounting hardware, impulse line penetrations, heater, or thermostat, but it is evident that fitting everything inside would be challenging if not impossible. In another example using a different enclosure manufacturer with slightly different dimensions, we have more width available, but compromised height (Figure 3). Note that the graphic shows no blowdown valves. Most, if not all, specifications (particularly condensing/liquid service) require blowdown valves inside the enclosure. Again, it’s evident there is not enough room to accommodate two of these valves in series on each impulse line.

Time allowing, one can specify and acquire an enclosure with custom dimensions. If it’s a one-off application, then perhaps this is the way to go. Depending on the actual upsize and the enclosure provider, this will likely result in a 40-50% cost increase and doubling, tripling or even quadrupling lead time. In a competitive bid situation involving hundreds of enclosures or in a tight execution window, this may well be untenable.

That’s why we generally recommend against using three instruments in one enclosure. The space available with approved enclosure providers makes this a difficult prospect for a shop integrator and even more difficult if it’s stick-built in the field.

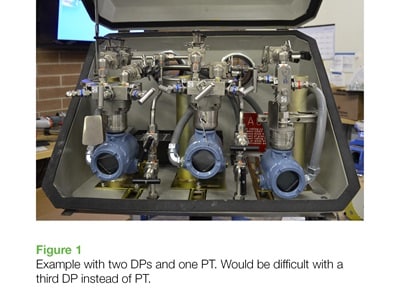

Instead, we suggest breaking out the triple DPs into a series of two separate enclosures: two DPs in a triple (Figure 4)and one DP into a single. For double DPs, we suggest placing these into a triple enclosure. In doing this, you ensure field access and maintainability with maintenance personnel having the ability to easily actuate all of the manifold and blowdown valves without pinch points, thereby ensuring safe, regular and effective instrumentation service in the best interest of the project. Having integrated over 1,000 enclosures of different kinds for a myriad of transmitter types and manufacturers we have seen the abounding issues presented with doing it otherwise.

Understanding this challenge and addressing it in early stages of project definition will allow the key stakeholders to make an informed decision based on budget and schedule to achieve success with the eventual field installation.