Finding the Proper Needle Valve: A Guide on the Types of Needle Valves and How They Apply to You

A Guide on the Types of Needle Valves and How They Apply to You

Needle valves are specified and categorized for several reasons. Some of the most common include shut off, isolation, flow control, and dampening of pressure spikes. Users oftentimes only look at the pressure, temperature and size of a valve when making their selection. There are other features within the valve that can affect whether it will meet your specific needs. Let’s take a look at what is available in needle valves to make certain you are utilizing the best valve for your application.

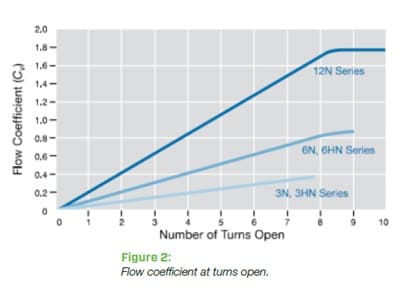

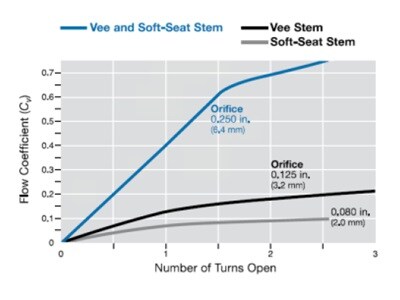

Many of us think of using a needle valve to accurately control the flow. Control applications require us to specify a regulating stem tip (Stem 1 as shown in Figure 1). Regulating stems tips are sometimes known as equal percentage stem tips. Each turn of the stem increases flow an equal amount. Figure 2 (courtesy of Swagelok) shows flow through a needle valve with its relationship to turns opening the valve (“0” would be the valve fully closed and “8” or “9” would be the valve fully open.) The regulating stem tip (blue lines) show continuously varied flow (increases in Cv) with eight or nine full turns (a turn is 360 rotation of the valve handle), allowing you to precisely control the flow coming out of the valve. When selecting a stem tip, using a regulating stem tip provides the best chance for controlling the flow.

A variety of handles are normally available. Handles will typically be plastic or metal, and either round or bar-shaped. Plastic handles are often available in a variety of colors, which can make selecting the correct valve easier for the operator. They also transmit less heat on hot applications, preventing burns. However, metal handles offer advantages as well. They usually can withstand the rough application of a wrench or pliers, which may break a plastic handle.

There are a wide variety of needle valves on the market. Needle valves offer features that can affect whether your needs will be met or not. Different needle valves are specified and categorized based upon their features and how they should be applied. Take time to be certain the valve you select will work for your intended application. Applying the correct needle valve offers a much higher chance of production and satisfaction.

This document was prepared by Swagelok Kansas City | Little Rock | Omaha | Quad Cities. The information and recommendations are intended as general information only, are subject to change without notice, have not been verified by Swagelok Company, and do not contain or create any warranty or guarantee regarding accuracy or completeness. Users bear responsibility for determining the suitability of information, recommendations, and products for their own use and situations. Consult catalogs on www.swagelok.com for the most current information about Swagelok products and services.