Process Analyzers: Improving Overall Reliability

Improving Overall Reliability

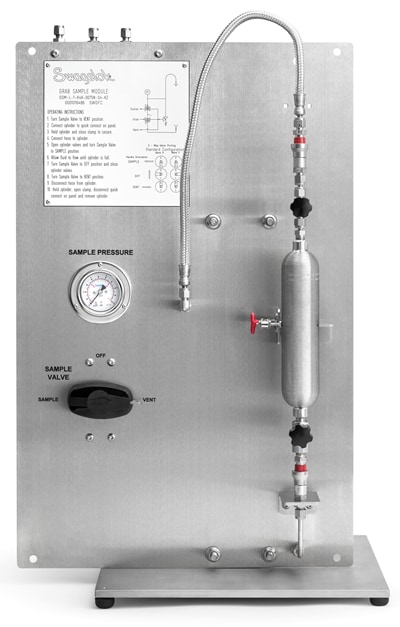

Sample systems are the facilities to extract, condition, and transport a sample from process to the online analyzer. Each of these steps has the potential to wreck the reliability of the analyzer. The designer must consider how the sample interacts with each component along the entire journey from tap to analyzer and how this may impact the reliability of the system as a whole. Sample systems are not very tolerant of design error; each error compounds, and eventually, the analyzer is plugged or exposed to incompatible process conditions. To design a reliable sample system, the designer must consider the entire path from process tap to the analyzer and how each component affects the sample as it travels through the system.

Even if the system were designed correctly, process conditions could change. A small change in pressure, temperature, or makeup could send the entire system spiraling into unplanned downtime costing the plant every minute. Whether facilitated through a third-party or in-house a simple way to monitor the process sampling conditions is to perform regular audits of the sampling system and sub-components and keep a record of their condition.

Often overlooked, the sample system is vital to utilizing the analyzer to its full engineered capacity. The sample system is the first line of defense in protecting the analyzer and providing it a representative and reliable sample. While a sample system might be orders of magnitude cheaper than the analyzer, an investment in correctly designing the sample system will only pay dividends down the line in overall reliability and analyzer performance.

* Clevett, Kenneth J. Process Analyzer Technology.

John Wiley & Sons, 1986.